CENTERLESS GRINDING MACHINE

Technical parts are usually conceived with tolerances, geometric shape errors and roughness that many times are more restricted, being difficult to be obtained in conventional processes, such as CNC and Multi-spindle lathes. One of the main equipment items used to meet increasingly stricter requirements is the grinding machine.

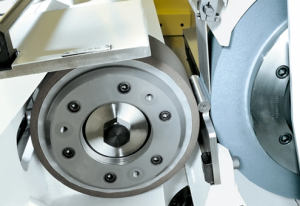

In this article, we will present the Centerless Grinding Machine Centerless or Passage Grinding Machine, which is an equipment comprised of two grindstones – one for dragging and other for cutting –, positioned facing each other. The dragging grindstone has the task of “spinning” the part so that the cutting grindstone can remove the material.

The product leans against a ruler, made of hard metal, ground and polished, so that it passes through the grindstones. This ruler is adjusted so that the product slides correctly and can ensure the tolerances assigned to the product.

The product finishing level is obtained through the type of grindstone used in the process, which may vary in the aspects of nature of the abrasive agent, grain size, grindstone hardness, structure, type of alloy, and speed with which the product passes through them. There is also the possibility of having two different grindstones in a single machine – the first deburring and the second finishing with polishing.

Samot has different Centerless Grinding Machines Centerless, with grindstone widths ranging from 300mm to 500mm, and can grind parts with 3mm to 100mm of diameters, in different finishing degrees.

Images:

- With the ability to resize parts with great efficiency and high precision, it meets specific finishes and meets customer requirements.