THE ERA OF ELECTRIC CARS

Global data confirm that vehicles with rechargeable batteries are the way forward to the automobile industry. Between 2015 and 2020, the growth reached 297%, figure that could be even more expressive if there wasn't the pandemic. In this scenario, the forecast is that half of the vehicles sold in the world in 20 years’ time will not burn any type of fuel.

Tesla, the electric car manufacturer, disclosed its results for Q3 2021. A total of 241.3 thousand cars were produced, breaking the record set in the previous quarter. This means that Tesla was able to grow in an instability scenario caused by the pandemic, by natural disasters in the USA, and by the lack of semiconductors crisis, which has led to stoppages in many factories around the world.

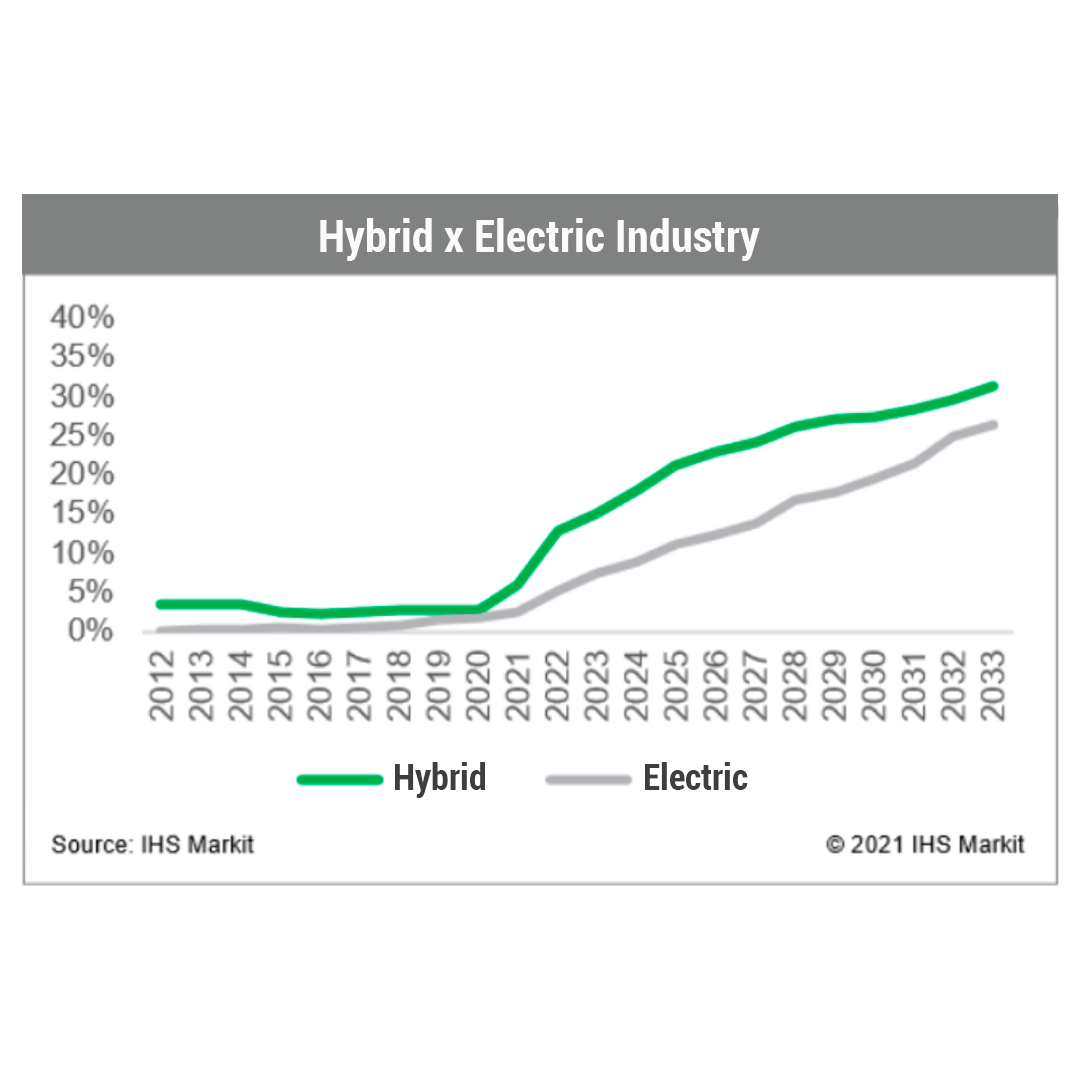

As the industry moves towards electrification, using a hybrid technology as a bridge for full electrification has been used as an inclusion strategy. For Brazil, the most feasible alternatives currently involve ethanol joining hybrid systems, and we already have national manufacturers actually using such combination.

The reason for both technologies presenting growth is due to the fact that batteries still have low autonomy and take a long time to be recharged, which encourages the use of hybrid systems until a 100% electric system is able to meet such demands. Another matter is that there is no full infrastructure to charge electric cars. But gradually we can see services and charging points adapting themselves to this innovative technology and will be part of a not-so-distant future.

Moreover, the shift to electric vehicles is related to international treaties, such as the Paris Agreement - which provides for the reduction of gas emissions and greenhouse effect until 2050 - added, of course, to the decrease in the availability of fossil fuels. Companies in the technology and automobile sectors have been searching for new and more sustainable components to improve those batteries. With this, Niobium is an option that can become the protagonist in the race of this market in this and in the next decade.

The use of electricity with a vegetable source fuel helps to balance the emissions, but it is a local solution. “The cost of charging an electric car is approximately four times lower in relation to a gas model by traveled kilometer”, says Evandro Mendes, CEO at Electricus, specializing in recharging structures.

In addition to electric cars, the bets on other vehicles are at full steam. The use of this technology in eVTOLS (electric vertical take-off and landing vehicles) is in the list when the subject is the future of mobility and automotive manufacturing.

Honda is the latest company to announce its own “flying car”, with expected launching in 2030. It will be equipped with a turbine and gas hybrid energy unit, as well as the electric battery. According to the brand, this technology solves the problem of the low autonomy of the batteries in aircrafts, allowing them to fly up to 400 km.

Automobile companies must be prepared and developing themselves to meet the demands ahead, since the electrification of vehicles is a global reality, and even if our country is not a pioneer on the subject, it is sure following on the footsteps of this new era.

At SAMOT, the parts can be created according to the profile used by the client, with a high-quality finishing through services such as anodizing, which also transforms it aesthetically, providing a matte, glossy, or colored decoration, if necessary. Furthermore, depending on the raw material used, we have ALTREF in our business group, specializing in aluminum rebars.

With the support of a large structure in the supply of machined parts, expertise and a qualified staff to monitor and meet the development of new projects, SAMOT business group accompanies this market development.