The importance of metrology in quality control in an industry

Introduction

The need to measure objects is very old and, for a long time, each people had their own measurement system, which was established from arbitrary and inaccurate units, such as, for example, the ones based on the human body (span, foot, inch, etc.). This caused a lot of conflict, because there wasn’t a standard established.

Industrial Metrology

In the late 19th century, the worldwide uniformity of measurements was acknowledged by the signature of the Meter Convention, signed by representatives from 17 countries, including Brazil. Since then, the diversity and complexity of measurements used in the industry, in international trade and in scientific research studies has grown tremendously, making a global measurement system indispensable.

Currently, metrology is mandatory in process control, in product, environment, health and safety quality assessment, in order to ensure safe trade practices and protect the end consumer, providing reliability, credibility, universality and quality.

For this purpose, it is necessary to measure as precisely and accurately as possible, obtaining results that are closer to the actual ones, identifying the needs for adjustments in processes or ensuring the reliability of established parameters. In this context, Samot invests in state-of-the-art technology and high-precision measurement equipment, such as coordinate measuring machines and optical scanner. máquina de medir por coordenadas and scanner óptico.

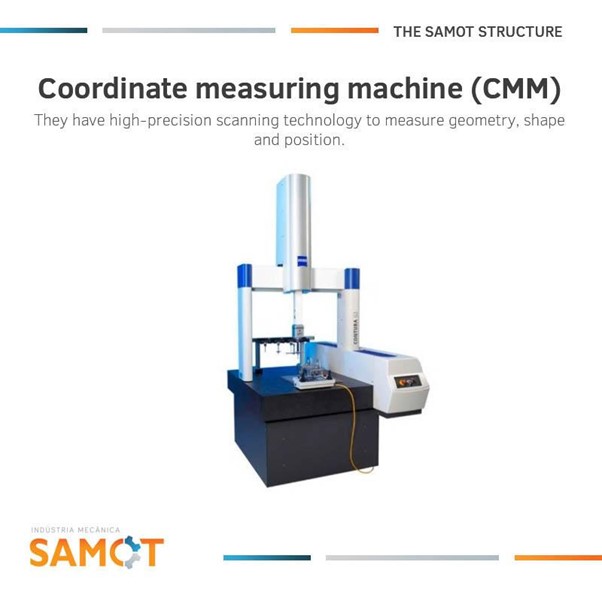

Coordinate measuring machine (CMM)

Coordinate measuring machines (CMM) are measuring devices based on the Cartesian system, with representation of points in an orthogonal system of coordinates (x, y, z). They have high-precision scanning technology to measure geometry, shape and position.

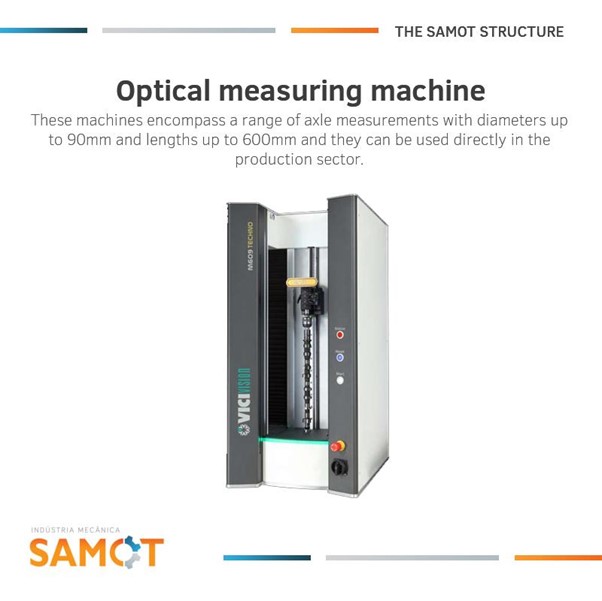

Optical Measuring Machines are used to measure lathed and milled parts, easy to execute, and also quickly obtain results with great efficiency. These machines encompass a range of axle measurements with diameters up to 90 mm and lengths up to 600 mm and they can be used directly in the production sector. Máquinas de Medição Óptica são utilizadas para medição de peças torneadas e retificadas, de fácil modo de execução, e ainda contam com rapidez na obtenção dos resultados e grande eficiência. Essas máquinas abrangem uma gama de medição de eixos com diâmetros de até 90 mm e comprimentos de até 600 mm e que podem ser usadas diretamente no setor produtivo.

Therefore, SAMOT is prepared to meet the customer needs the best way possible, including high-quality equipment in this process and ensuring the best finishing in product delivery.