Tests with Materials and Metallographic Laboratory SAMOT

In past centuries the process for manufacturing most products was conducted in a handcrafted way, with no need for regular control of the products manufactured. For example, it was possible to assess the hardness of a shaft, the quality of the surface, coating or paint, simply by using the product.In that way, the quality of several components was only validated after conducting functionality tests for the entire set on field and in conditions of application.

Laboratories Metallographic

Currently, it is understood that the quality of the product is related to the quality of raw materials,and that tests must be conducted on the materials throughout the production process, including finished products testing.With this scenario, it is possible to notice the importance of testing the materials, and through such tests the suitability to the properties that will make them adequate for each use become evident.

In known materials, the results are achieved through countless tests, compared with values established on requirements from clients and standards on materials. Such requirements are Mechanical, Chemical and/or Metallographic in nature. Therefore, it is possible to notice that the comparison between results from testing and the requirements established is crucial for the acceptance or rejection of the material as apt for use in a certain application, which implies having proper, duly calibrated equipment.

Within this context, Samot has invested throughout the years in test equipment items that provide the maximum accuracy and reliability,such as Traction Testing Machine, Optical Microscopes, Eddy Current equipment and Cleanliness Testing Microscope.

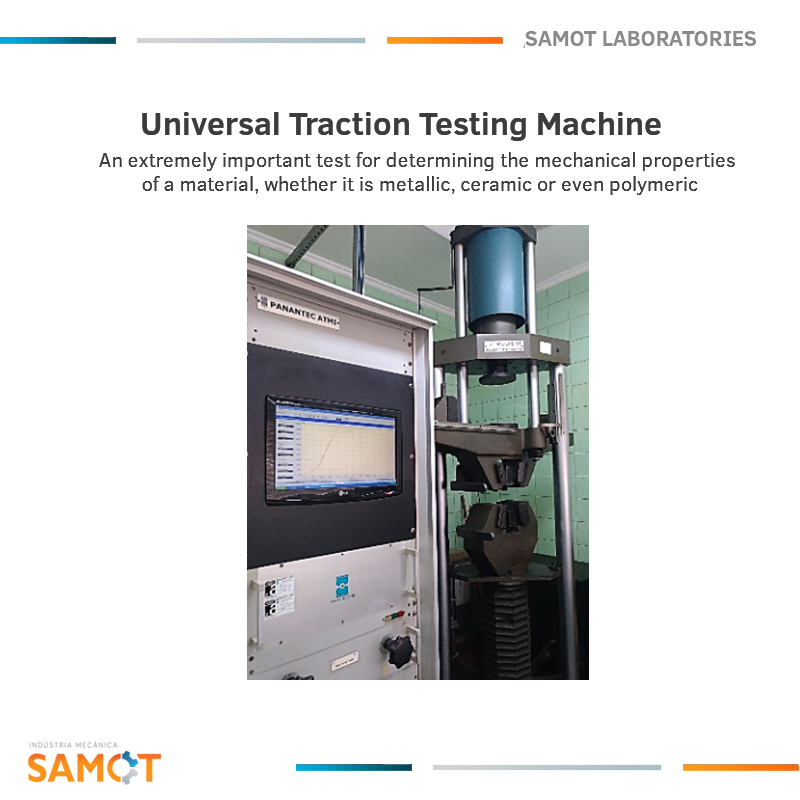

Universal Traction Testing Machine

The Traction Testing is extremely important for determining the mechanical properties of a material, whether it is metallic, ceramic or even polymeric. From the results achieved, it is possible to check the maximum force the test body can withstand, representing how the analyzed material would react to a certain condition of application. Through elastic and plastic deformation, it is possible to obtain data on Elastic Limit and Elasticity Module, Yield Limit, Resistance Limit, Rupture Limit, as well as the percentage of Reduction/Narrowing of Area and final Stretching.

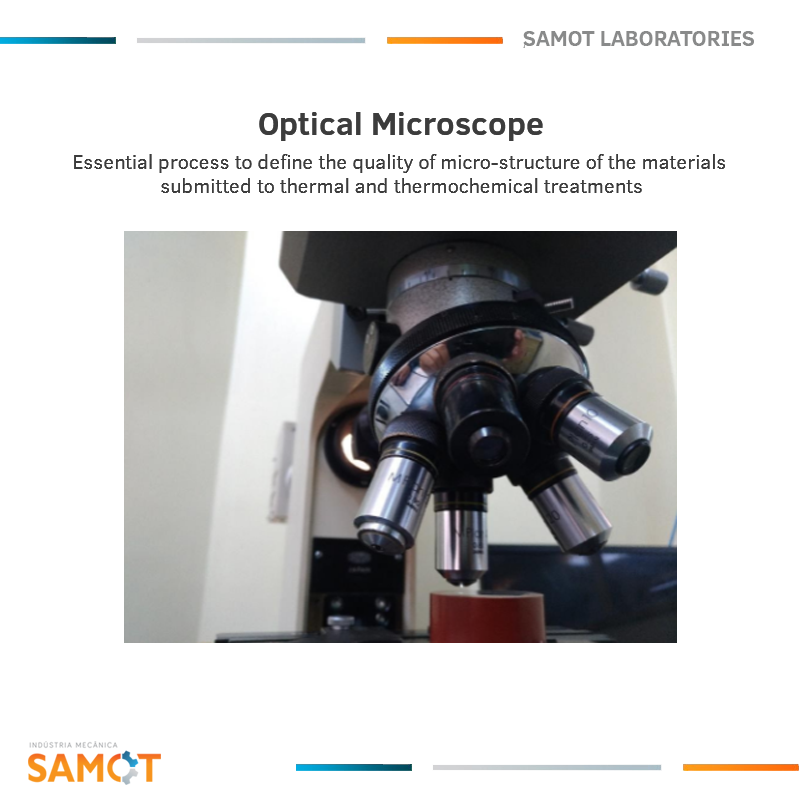

Optical Microscope

In the metal processing area, it is crucial to conduct Metallographic Analyses, which allow assessing micro-structural features of the samples. Some examples of these defects are: internal discontinuities, cracks, micro cracks, coating layers, surface treatments, size of ferrite grains, austenite grains, among others.

The optical microscopy analysis is heavily used in studies and characterizations of materials. This type of testing is extremely important to define the quality of the micro-structure of materials submitted to thermal and thermochemical treatments, whether they are conducted to increase the mechanical resistance, deterioration, or even to improve other aspects of the materials, such as machinability.

Eddy Current

Eddy Current Tests are widely used in the automotive and airspace industries and in other manufacturing and service segments that require inspection of fine metals. The procedure is based on the physics phenomenon of electromagnetic induction, where a eddy current probe, an alternate current, flows through a coil and generates an oscillating magnetic field.

Portable instruments are capable of meeting a wide range of testing needs, and different types of coils allow conducting tests on products with many geometric shapes, provided that the material to be analyzed has electric conduction properties.

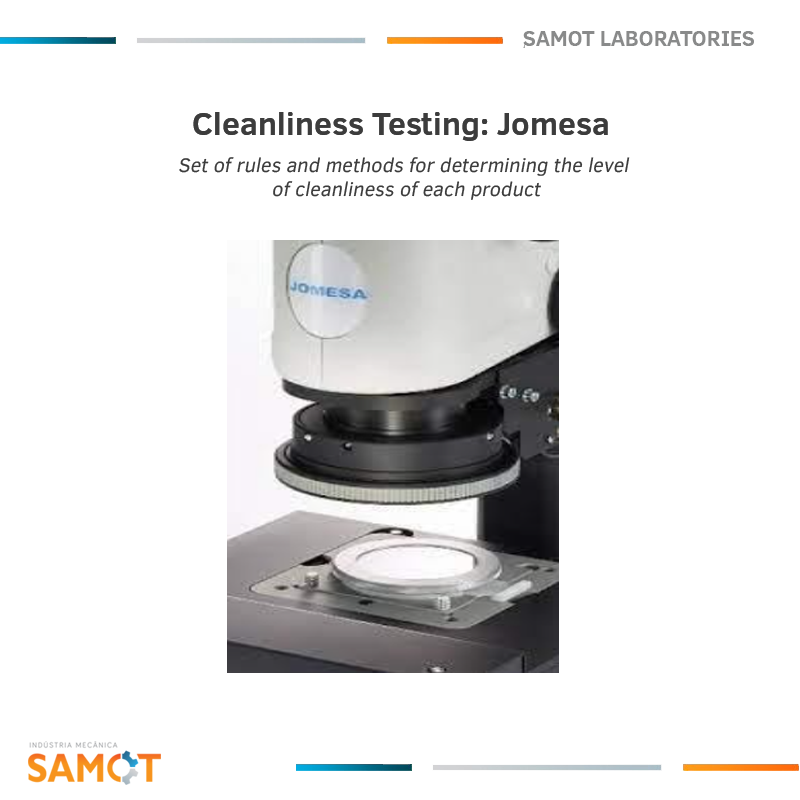

Cleanliness Test – Jomesa

The Technical Cleanliness Tests, a set of standards and methods for determining the level of cleanliness of each product, are conducted through standardized methods and analyses, with the goal of classifying classes of acceptable particles in different components, according to the respective applications.

Automobile companies are on the forefront when it comes to Cleanliness – with parts and precision systems for combustion engines and components, this testing category has been increasingly requested over the past few years. Currently, an increasing number of automotive parts has requirements specified concerning the level of cleanliness, and, in addition to dimension tolerances, technical drawings of parts already present codes the part must comply with, such as CCC (Component Cleanliness Code). The increasingly lower tolerance of components make systems must sensitive to dirt and dragging of particles.

With a market differential such as the Jomesa and Eddy Currentequipment, our integrated laboratory is dedicated to tests such as these. This way, we guarantee the quality since the analyses of raw materials, going through all tests necessary to ensure the service and satisfaction of our clients, complying with international rules and standards!