Lean Philosophy

What is a Lean Philosophy?

Lean philosophy is focused on reducing waste and eliminating processes that do not add value, and is also known as the Toyota production system (developed in Japan between the 1950s and 1960s). This management system has several work tools that seek to prioritize continuous improvement. Even though it is usually applied in the production area, it can be used throughout the organization Lean é “enxuto”, ou seja, é uma filosofia que foca na redução de desperdícios e na eliminação de processos que não agregam valor, também conhecido como sistema Toyota de produção (desenvolvido no Japão entre as décadas de 50 e 60). Através desse sistema de gestão que conta com diversas ferramentas de trabalho, busca-se priorizar a melhoria contínua, embora geralmente seja aplicado na área de produção, pode ser utilizado em toda a organização.

The Lean philosophy is based on five basic principles: identifying which activities add value to the client; mapping the value stream to identify waste; creating continuous flow for running the process; establishing a customer-pulled production; and seeking constant perfection. It is a body of knowledge whose essence is the capacity of continuously eliminating waste and solving problems in a systematic way. That implies in reshaping the way one leads, manages and develops people. It is through the full engagement of the people involved in the job that one can envision the opportunities for improvement and sustainable gains. Some of the following tools can be applied to this management system: JIT: Just in time. Jidoka. Heijunka. Poka-yoke. Kaizen.

Why is Lean Management important?

There are tools that allow the implementation of the Lean philosophy, such as the mapping of the company’s value stream, which maps and improves the performance of the entire production flow, from the ordering of raw material to the end consumer. For such, a pull-production system is used, based on the client’s request, allowing to eliminate waste such as storage of unnecessary inventory, occupation of more space than required, and excessive work time. Additionally, the Lean philosophy allows to eliminate several other types of waste, such as super-production, intellectual waste, unnecessary movements, transport, waiting time, defects and rework, and unnecessary processes.

With them in place, the process efficiency is constantly improved, since everything that does not add value to the product is removed (that is, costs that can be avoided by the company), and waste is also continuously avoided. Furthermore, the methodology also allows for a clear identification of the problems contained in the process, allowing the fastest solution possible.

How SAMOT uses Lean

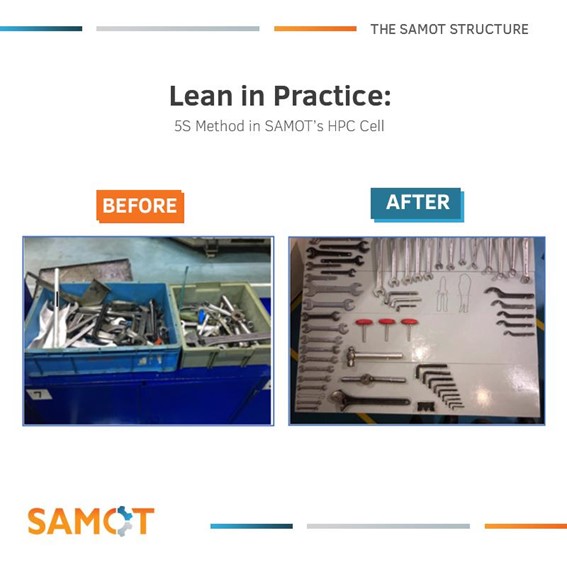

SAMOT’s culture has been shifting with the Lean philosophy in several areas. An example of this evolution is the use of 5S, a methodology that helps create the habit of discipline, identify problems, and generate opportunities for improvement.

The Purpose of 5S

The main purpose of the 5S methodology is to shift the way the employees think in order to have a better behavior, both in their private lives and at the company. This creates a more productive environment, with quality of life, which is essential when seeking the best results. Here are some examples of its benefits:

• Promoting a clean, pleasant, and safe place to work;

• Improving the organization of sectors, work documents, and installations;

• Developing and applying concepts of standardized work;

• Changing the behavior, aiming at increasing productivity;

• Meeting client requirements, as well as any legal and other obligations;

• Reducing waste and costs.

Exemplos de Aplicação na SAMOT